As air traffic across the globe continues to gather pace post-pandemic, the rising cost of attritional claims has once again become a key focus, writes John Bayley of McLarens Aviation.

Attritional claims costs in aviation business are on the rise, despite the underlying safety of the aviation industry improving markedly in recent decades, and major losses on a regular Hull Policy being relatively infrequent.

In a segment of the insurance market where ‘attritional’ claims often count as those under $10m, this is a significant issue.

So, what’s behind these rising costs and what does it mean from a risk management perspective?

From the adoption of new materials in manufacturing to the impact of inflation, there are a number of factors at play.

New Generation Aircraft

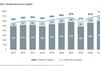

During the Covid pandemic airlines accelerated the retirement of older aircraft, inevitably favouring the newer more fuel-efficient types. This has been further reinforced with the return of higher oil prices and the global economic downturn.

The Boeing 737 MAX has returned to airline operations and the delivery rate of the latest generation Airbus narrow body fleet is increasing. The Boeing 787 and Airbus A350 continue to attract new orders and we can see that the global fleet is moving towards a higher percentage of new technology aircraft both in terms of composite airframe construction and the new generation of turbo fan engines.

The technology of these aircraft is such that conventional structural repair methods, which are more straightforward and readily available, are not applicable to a large number of aircraft of many sizes and types.

For some models with new materials many damage events require manufacturer’s support. due to the specialist skills, equipment and material involved. The independent maintenance organisations and airline engineering departments are, in the case of significant damage, limited in the scope of repairs they can perform. This inevitably results in costs increasing significantly when damage to composite primary structures is compared to that of the previous generation of airframes.

Similar issues are arising on other parts of the aircraft which have traditionally been made from composite materials, i.e. nacelle components such as inlet cowlings and thrust reversers. Previously such parts would have a good degree of repairability and there was an abundance of capability in the industry to perform such repairs.

With the latest generation of aircraft, the manufacturers have been less inclined to invest in repairs and it is now often the case that the components are repaired through the replacement of sub-assemblies, as opposed to the more cost-effective option of repairing those sub-assemblies. Sometimes when a repair is going to be performed, the repair development costs which are within a quote can be eye wateringly high.

New Engine Options

Airliner engine damage caused by Foreign Object Debris (FOD) accounts for a large percentage of the attritional claims handled by the McLarens’ global network of aviation offices. In some events, the damage can be repaired “on-wing”, in the remaining cases the engine will need to be submitted to a repair shop which can result in costs running to millions of dollars.

We are seeing a paradigm shift in narrow body aircraft engine technology. The design of the latest engines offers many of the advantages seen with the large turbo fans, one of which is an improvement in FOD resilience. The downside is that the design and limited repair options is such that high-cost parts will inevitably be scrapped as opposed to being repaired. We are already seeing examples of the cost of repairing these engines being high and with the complexity and, in some areas, limited repair scopes for independent shops to be involved, there are limited market forces competing on the cost options.

Global Inflation Effects

Beyond the specific claim cost increases resulting from the latest generation of airframes and engines, the cost of new parts has increased across the board as a result of global price inflation and in some cases the availability of raw materials and components which has been affected by international events. There are few ways to mitigate this when new parts are the only option. The positive is that for the numerous older generation aircraft that remain in service there is a healthy market for competitively priced used parts due to the high number of aircraft that have been parted out.

Risk Management

Clearly in the current environment reducing risk is more important than ever. The majority of airlines proactively work to reduce their risks, as do bodies such as IATA through the Operational Safety Audit (IOSA) and Safety Audit for Ground Operation (ISAGO) programmes. The human interface and operational environment will always create scenarios that combine to cause losses, particularly as the industry recovers and resources become stretched.

For aviation insurers, risk mitigation is a primary consideration and, where appropriate, they may take a more active approach to assessing an insured’s risk profile by using specialist organisations such as McLarens to review their operation and make recommendations to reduce risk. These assessments are almost always beneficial, particularly if they are followed up on.

A longer-term approach

Long term planning for aircraft operations requires many long-term partnerships, including the choice of broker and insurers. Any significant repair need requires the involvement of all the relevant stakeholders. All payments require supporting detail, and it can often be a long process of review and assessment requiring the cooperation of all parties in one way or another. Getting to know the appointed Adjuster before a major repair need is a good way to minimise delays.

It is not uncommon to receive quotes on a fixed price basis and whilst this gives some certainty for repair budget planning, the experience of many adjusters will show that these fixed costs contain an element for contingencies which are rarely brought into play. Repairs offered on this basis often provide a nice profit cushion, but insurance is not in place for this reason so these generate debate on a regular basis.

Any adjusting firm has a role and obligation to keep up with industry technology by recruiting new talent, understanding the latest developments of repair needs and the related availability of options. Adjusters must always consider how efficiency of work and costs is applied, both from an insured or insurer’s perspective, and bring these points to light for proper consideration. As technology develops there is much more to learn and whilst most of us learnt to cut metal that has held well for decades (and still has a future) the composite world is a new set of skills and knowledge we relish the challenge of working in.

John Bayley | McLarens Aviation

Regional Director, Europe

No comments yet